Lighting and Busbar Power Distribution Systems

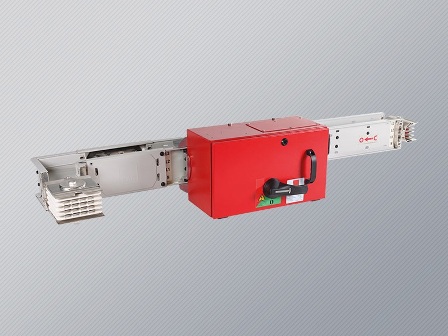

Busbar Trunking System

Busbar trunking system; In the 1930s, it emerged mainly in America, as a need of changing production technologies in high-rise buildings and factories.

It started to be used in Japan and Europe in 1950s. The busbar trunking system manufacture in Turkey; It started in the 1970s.

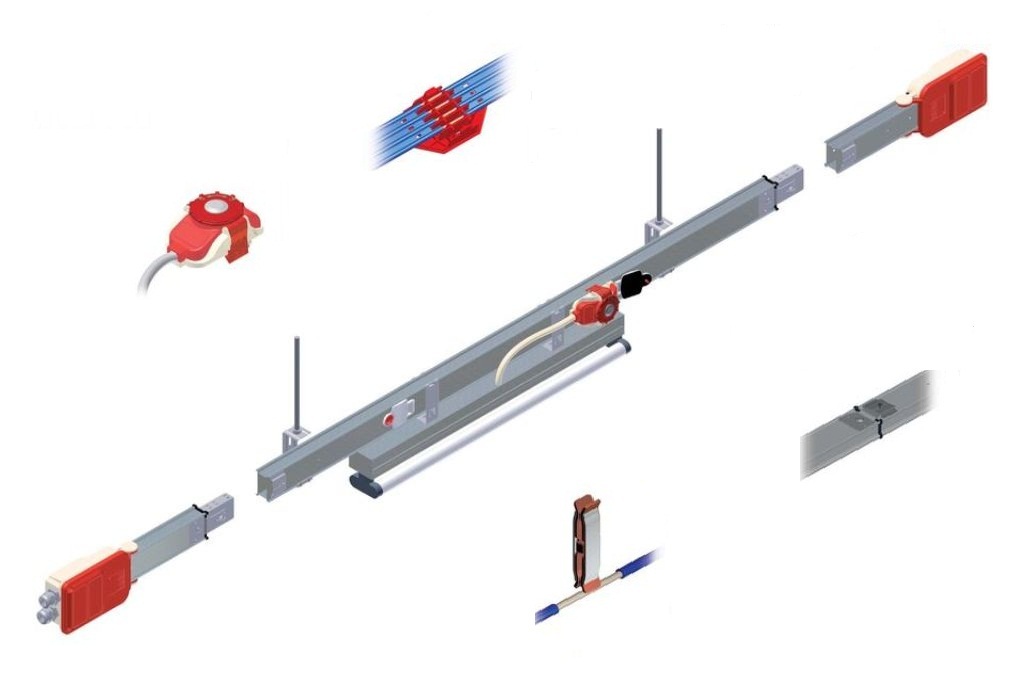

Busbar energy distribution systems; With its modular structure, it responds to all kinds of power requirements in modern enterprises and buildings. It provides the possibility to change the settlements, machine additions, energy supply to various points without disrupting the working parts of the plant.

In the sheet metal and aluminum housing, it is possible to get the energy distributed by the insulated busbars through the special outlet units without interrupting the energy safely from the desired points.

Busbar systems, which have international standards compliance test certificates, can be expanded, changed, moved and reused if desired. It is very easy, economical and safe to take energy from the desired points along the busbar route with the exit boxes.

Busbar Current Carrying Capacities

Busbar MV: Provides energy transmission and distribution in current stages from 950A to 5700A (Medium Voltage MV Busbar: Metal protected on cast resin protection). The conductors are preferably aluminum or electrolytic copper.

Busbar KX: It provides energy transmission and distribution in the current stages between 400A and 6300A (Tin-coated Aluminum busbar or Copper busbar conductor).

Busbar CR (Cast Resin Busbar): It provides the energy transmission and distribution in the current stages between 630A and 6300A (Tin-coated Aluminum busbar or Copper busbar conductor).

Busbar KB: Provides energy transmission and distribution in the current stages between 800A and 6300A (Tin-coated Aluminum busbar or Copper busbar conductor).

Busbar KO-II: Provides energy transmission and distribution in the current stages between 160A and 800A (Tin-coated Aluminum busbar or Copper busbar conductor).

Busbar MK: Provides power transmission and distribution in 100A to 225A current stages (Tin-coated Aluminum busbar or Copper busbar conductor).

What is the bolt-on busbar?

Bolt-on busbar system: Busbar systems that enable the busbar system to be energized via the modular additional points of the busbar output boxes.

Bolt-on: It is used in the busbar system where it is required to take current from the additional points and in the places where direct feeding is done.

What is a plug-in busbar?

Plug-in busbar system: Busbar systems that enable to receive energy by means of power take-off boxes through the plug-in outlet windows on the body of the busbar system.

Plug-in: It is used when it is required to take current from plug-in window with additional points in busbar system. (Flat modules only)

LONG LIFE

Busbar systems have special maintenance-free structural features. Each part of the system is modular and can be easily removed and installed. If necessary, the entire system can be easily moved to another location.

MODERN VIEW

Busbar systems give businesses a modern look as well as functional use.

FLEXIBILITY AND ECONOMY

Busbar Systems provide easy, economical, fast and modern solutions to the displacement of machines and similar equipment in enterprises with modular structures and superior features. All modifications and additions can be made easily without stopping the operation.